Efficient and safe transportation of various tools from the ground to the drill floor are top priorities when it comes to oil and gas drilling. A catwalk system accomplishes this and serves to cut down on labor as well as enhances safety. It is important for workers in the oilfield to know about the various types of catwalks used and to understand the differences between each catwalk system.

What is a catwalk in terms of oil and gas extraction? What are its functions?

One of the frequently asked questions related to oil and gas extraction is ‘what is a catwalk?’

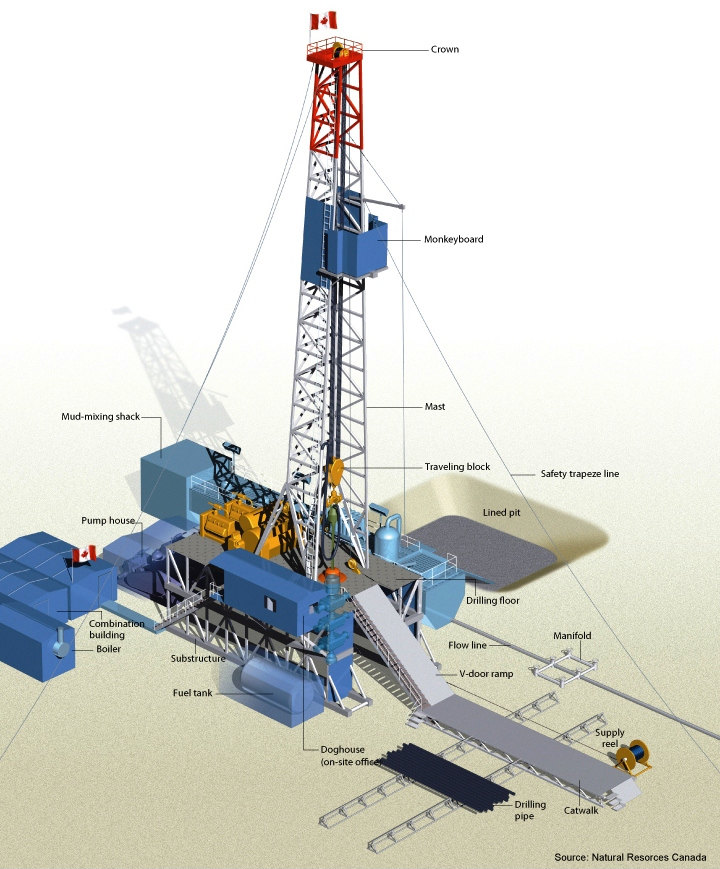

Catwalks are rectangular, long platforms that measure about 0.9 meters in height and are typically made of steel. They are situated perpendicular to the ‘V-shaped’ opening (Vee door) in the derrick. Catwalks are connected by a pipe ramp to the rig floor.

The function of the catwalk is as a staging area for drilling tool activities, components, or tools that are going to pick up or the ones already run and about to be laid down. However, it is also crucial for overall safety in the field. Well-designed catwalks create an efficient and safe rig site by minimizing operating hazards and tubular handling.

What types of catwalks are usually used in oil and gas extraction?

From hydraulic catwalks to power catwalks, many types of catwalks are used in oil and gas drilling.

Oilfield catwalk: Mechanized catwalk system

A mechanized catwalk system speeds up and simplifies pipe handling all the way to the drill floor from the pipe rack. The pipes can be picked up directly by an elevator by lifting them up to the drill floor. This eliminates the need for interim storage that is time-consuming. Personnel can operate the oilfield catwalk system from the drill floor using a remote-control panel that eliminates safety risks. By splitting it into elevator units and main units, it is easy to transport the oilfield catwalk system.

Hydraulic catwalk

A Hydraulic catwalk helps in the safe transportation of tubular and pipes during the process of pick up and lay down. This is a push-pull type of catwalk that utilizes a ramp and skate. Being hydraulic powered, the catwalk is controlled with a manual control box while a wireless remote control can also be used to operate the hydraulic catwalk.

The main structure of the hydraulic catwalk is the base that includes Kickers and Indexers. From the base, the adjustable v-door extends to the rig floor. A manual joystick is used to adjust the v-door and to control the hydraulic cylinders beneath the catwalk. The skate is used to move tubular from and to the rig floor which is operated on a cable drive system.

Automated catwalk

An automated catwalk eliminates almost all human interactions with pipes or tubular during the processes of pickup and laydown in the rig. This helps to optimize safety by preventing accidents related to high-risk activities.

An automated catwalk delivers the casing to the floor of the drill and gets rid of the requirement for additional specialized services on the wellsite. The automated catwalk offers the ideal combination of enhanced efficiency and improved safety are rapidly becoming the preferred equipment in oil and gas drilling.

Also called a power catwalk, the automated catwalk is powered by electricity while a wireless remote can be used to control the catwalk. Infrared sensing technology utilizes motion detection sensors to automatically shut the catwalk operations whenever there is unauthorized access to a restricted area. A key feature of the power catwalk is the integration of the hydraulic station with the cat track body that makes transportation convenient.

Conclusion

A catwalk system is the vital component of the oil and gas drilling operations. Oilfield catwalk is typically used on sites of oil and gas drilling as the staging area where tools are kept. As a raised rectangular platform, the oilfield catwalk allows workers on the site to reach high up all the way to the rigs and place the required materials up there. The catwalk allows workers to just walk to the raised platform instead of getting down all the way from the rig to get the tool they need. They also ensure materials are raised and stored on the rig efficiently and safely.

A catwalk system is designed to ensure optimum safety of workers and the rig while the oilfield catwalk lowers total recordable incidents’ risk. The no-deck design of the catwalk system minimizes the risk of falls on the site. Modern catwalks are not only fully automated but are enabled with motion sensors and RFID technology apart from remote control functions. Knowing the features and functions of different catwalks will help workers on-site optimize safety and operational efficiency.