Numerous factors determine a good design for a catwalk to be used in the oil and gas industry. In this article, we shall explore some of these factors that would help those who work in designing oilfield catwalks.

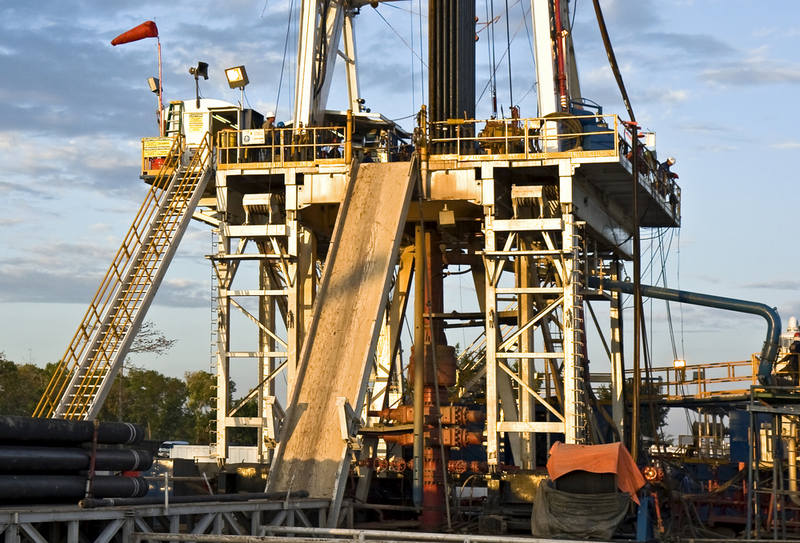

Catwalks are large and raised rectangular areas that are made with steel and placed perpendicular to a door located at the bottom of a slide. A catwalk is used to stage a variety of construction tools and objects that need to be picked up, used for operations, and laid down. Catwalks assist workers with storing materials and obtaining them whenever needed while they are performing an oilfield drilling job. Not just with allowing ease, but catwalks are there to ensure that a worker is safe on their rig.

Designing catwalks

When designing catwalks, builders need to consider several aspects that would guide the construction process. Catwalks need to be designed in a way that safeguards workers from falling into hazardous areas. The catwalk structural plan must comply with local building codes and are created by a welder who has current certifications. Since the oil and gas industry involves heavy-duty jobs, catwalks must be efficient and made with advanced engineering technology.

FACTORS INFLUENCING DESIGN OF AN OILFIELD CATWALK

A catwalk that has been well-designed can effectively reduce tubular handling and occupational hazards associated with working in the oil and gas industry. It also helps to keep your rigs safe and efficient while improving your profitability. In this section, we shall look at some of the factors that influence the proper design of an oilfield catwalk.

Occupational safety

In the oil and gas industry, safety is among the most important considerations. This is because the work environment in this industry involves exposure to hazardous products such as chemicals, hydrocarbons, and other compounds. These components are known to pose health risks and safety threats to personnel due to which the construction of materials needs to integrate health and safety concerns.

Catwalk manufacturing companies should comply with Occupational Safety and Health Administration (OSHA) standards. As part of the guidelines, high drill floors located in areas that have very high formation pressures must use hydraulic catwalks. Hydraulic catwalks are also required in places that have larger well servicing and drilling rigs since they cater to safety needs.

To design a catwalk that is ideal for oilfields, a welder should make sure that loaded pipes cannot be ejected from troughs during the pickup and laying processes. Interlock mechanisms should keep all the pipes secured until the tubular are in an ideal shape.

Sensors assessing proximity could be used to detect the presence of pipes at the end of troughs and create an interlocking system that stops unexpected pipe movement from occurring.

Technological advancements

A combination of multiple products is assembled to develop catwalks. Ensuring that these products feature the latest developments in technology is useful for enhancing efficiency. A feature like optional wireless control can help to remove rig workers from potentially dangerous areas. Remote connectivity options and monitoring based on conditions could also help enhance the safety of workers.

Practical construction

Heavy-duty jobs such as those involved in the oil and gas industry require practically designed catwalks. Having several essential constituents can make your catwalk more industrially acceptable. Welders should ensure that energy chains suited for long travels carrying large amounts of weight are present. A good interior separation system could easily raise the life of your cables.

Servo cables that are oil-resistant and suited for offshore applications are also useful. These cables are best for heavy-duty jobs and must be resistant to UV rays and flames. Similarly, data cables and control cables must be present to support large travel distances. They must be resistant to oils like bio-oils and be available for both indoor and outdoor use.

Adapted to the purpose

Catwalk builders should keep in mind the design requirements that would best enable oilfield workers to do their jobs. Wide working platforms that can support the smooth running of traditional operations without much hassle are convenient for users. Installing accommodation for all pipe rack heights and a good tubular delivery length is essential. A stabilizing system that is deployed hydraulically and long trough extensions would make operations more manageable.

IMPORTANCE OF OILFIELD CATWALK DESIGN

Finding the right design and construction materials for your oilfield catwalk is vital. As an industry, oil and gas are among the largest employers globally.

Ensuring that your catwalk is safely designed will provide fall protection and minimize occupational hazards associated with this industry. It will also allow workers to do their jobs with relative ease, comfort, and accuracy which will in turn improve productivity. Ultimately, a catwalk that has been designed carefully can be beneficial for the environment by reducing usual drilling rig hazards and preventing damage from happening to the surroundings.